Plate type truck jumper wire

(connecting wires for batteries)

Plate type truck jumper wire

(connecting wires for batteries)

DJ Series

MADE IN JAPAN

Proof of safety & confidence: "MADE IN JAPAN". We have developed plate type truck jumper wires (connecting wires for batteries) which first adopted "oxygen-free copper" with excellent conductivity as a terminal material in Japan. They are gaining a high reputation as the environment-friendly products having excellent characteristics that meet the requirements of professional mechanics.

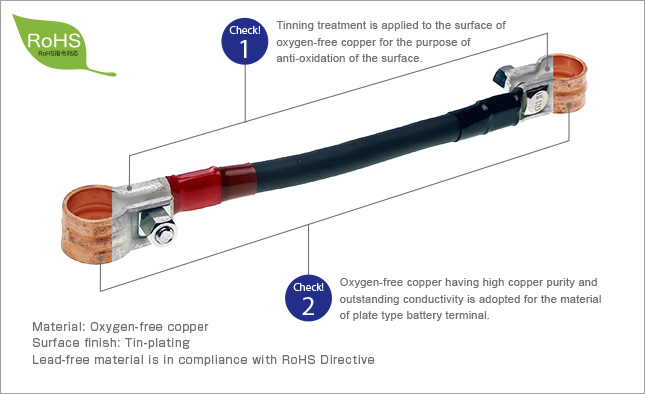

Remarkable point 2

Oxygen-free copper having high copper purity and outstanding conductivity is adopted for the material of plate type battery terminal.

What is Oxygen-Free Copper?

| Material | Component | Feature | Examples of material use |

|---|---|---|---|

| Oxygen-Free Copper (JIS:C 1020) | Copper content rate: 99.96% or more | High-purity copper having properties of excellent conductivity, in which impurities contained are reduced to the minimum. It is often used as a material for electronic components, which has excellent malleability, fatigue resistance, corrosion resistance, and weather resistance. | Parts used for wiring circuit connection of generators, switchboards, audio equipment, etc. |

*Malleability: The property of material to evenly stretch and extend without being destroyed, even when it is pressed and stretched beyond its elastic limit.

Reference: Comparison list of conductivities of various materials

| Compared materials | Oxygen-Free Copper * Materials used by products | Brass | Zinc alloy diecasting | Lead |

|---|---|---|---|---|

| Material conductivity (IACS) | 101% | 28% | 26% | 9% |

*1. Material conductivity refers to the internationally adopted standard annealed mild copper as a standard of electric resistance, which is specified as 100%IACS conductivity.

*2. Above values are just general reference values (standards), not absolute values (guaranteed values)

Reference: Plating treatments used on automotive repair battery terminals

| Type of plating | Plating compatibility in automobile parts | Features | Example of products compatible |

|---|---|---|---|

| Tin-plating | Japan Industrial Standards(JIS) Automobile parts - General rules of electroplating | Plating applied mainly for corrosion and rust protection purposes |

|

| Copper plating |

| ||

| Brass plating | - | Plating applied mainly for decorative purposes |

|

Usage environment grades specified in Automobile parts-General rules of electroplating

| JIS grade | Usage environment |

|---|---|

| Grade 4 | Outside of the vehicle exposed to harsh environments |

| Grade 3 | Outside of the vehicle in ordinary environments |

| Grade 2 | Inside of the vehicle exposed to harsh environments |

| Grade 1 | Inside of the vehicle in ordinary environments |

Usage environments of plated products are classified into the above listed four grades

Usage environment JIS grade for each plating type specified in Automobile parts-General rules of electroplating

| Type of plating | JIS grade |

|---|---|

| Tin-plating | Grade 4 |

| Copper plating | - |

*1:No description on usage environment grade for copper plating under Automobile parts - General rules of electroplating

`2:Brass plating is omitted due to no stipulation under Automobile parts - General rules of electroplating

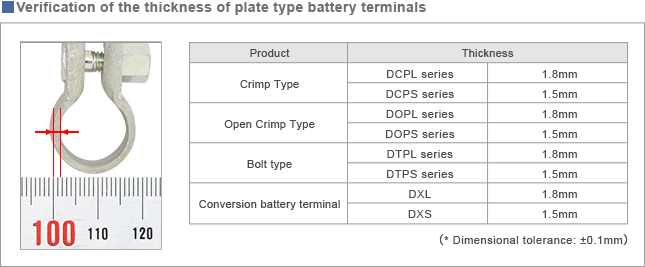

Remarkable point 3

To fulfill the battery' s function under the harsh environment in the engine room, we investigated 'the increment of the thickness' and 'slitless structure' of the battery terminals.

| Development concept | Reason and background |

|---|---|

| Thickness of terminal |

*Synergistic effect of Oxygen free copper |

| Slitless structure |

|

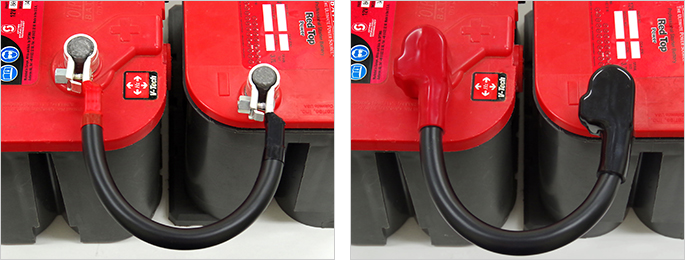

Reference: Verification of practical use examples of battery terminals with slits

The cracked battery terminal can causes 'contact

failure' and 'Voltage reduction' and fall into the

troubles of the vehicles.

Remarkable point 4

For our plate type truck jumper wires (connecting wires for batteries), we have developed RoHS Directive-compliant products which do not use any hazardous substances such as "lead, mercury, and cadmium" first in the industry. We have implemented environment-friendly manufacturing of these products which satisfy the needs of the times as well as support the preservation of the global environment.

Remarkable point 5

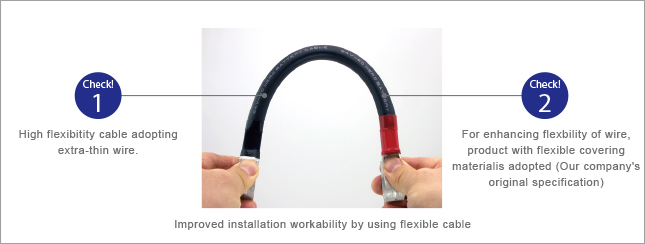

We have developed flexible electric wires under our original specifications to meet the request from the market which demanded "plate type truck jumper wires (connecting wires for batteries) with more flexible wires".

Beneficial advice for using the products

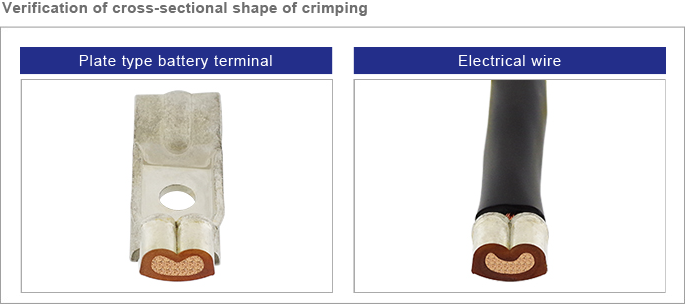

Storage batteries installed in large vehicles such as trucks and buses have especially large vibrations transmitted from the vehicle. We therefore recognize that our plate type truck jumper wires (connecting wires for batteries) need to have performance/function resistant to use in the harsh environment. We adopt a secure crimping method using a press to ensure high reliability.

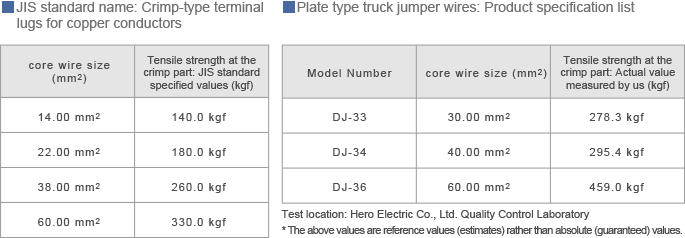

Reference: Verification of the tensile strength at the crimp part of electric wires

The terminals employed in our plate type truck jumper wires are "open type". Since the Crimp-type terminal lugs for copper conductors specified in the JIS Standards are "closed type", the above actual values are only for reference.

| Product | Model Number | Specifications | Materials | ||

|---|---|---|---|---|---|

| core wire size(mm2) | Distance between poles (mm) | Electric Wire | Terminal | ||

|

DJ-23 | 30.00 | 200 | Low-voltage Wires for Automobiles (AV) (Ourcompany's original specification) | Oxygen-Free Copper |

| DJ-33 | 30.00 | 300 | |||

| DJ-34 | 40.00 | 300 | |||

| DJ-26 | 60.00 | 200 | |||

| DJ-36 | 60.00 | 300 | |||

|

DJ-34RB (With Terminal cover) | 40.00 | 300 | ||

| DJ-36RB(With Terminal cover) | 60.00 | 300 | |||