Battery terminal

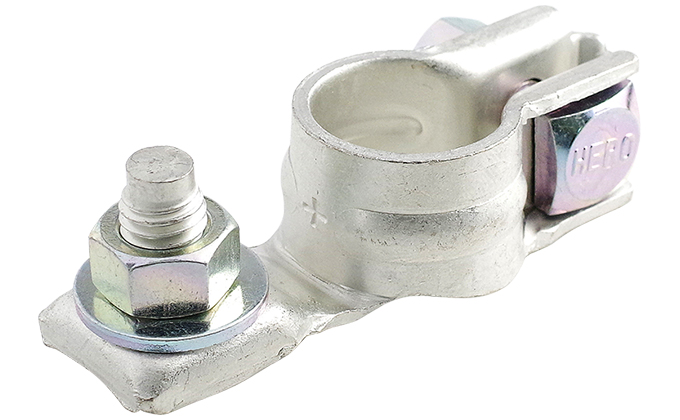

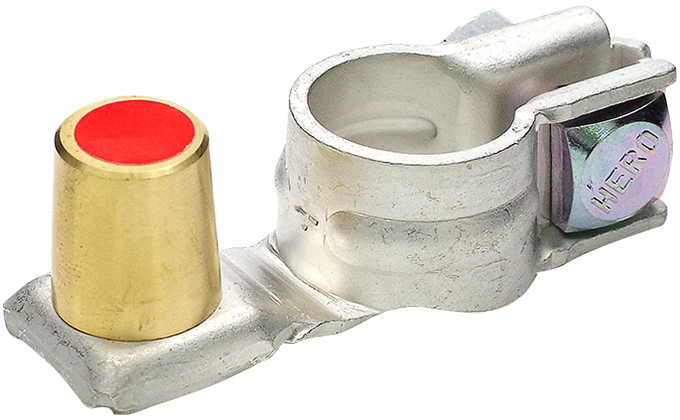

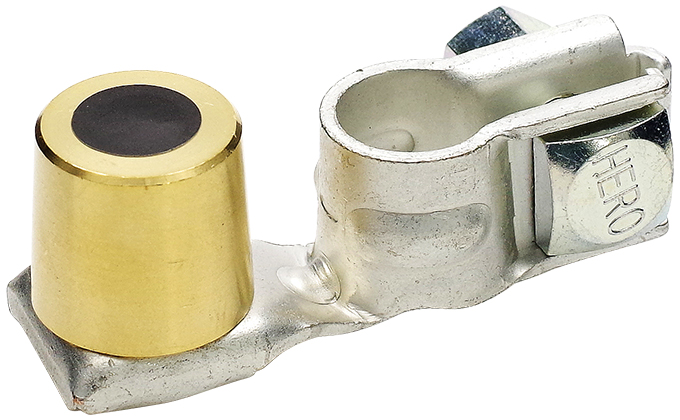

Playte type battery terminal

D-type

MADE IN JAPAN

The proof of confidence and reliance: "MADE IN JAPAN"

From planning to manufacturing, we adhere to domestic products and inquire the high quality and reliance.

We have been supplying automotive appliances to mechanics for more than 30 years, and make good use of experiences to the products.

Remarkable point 2

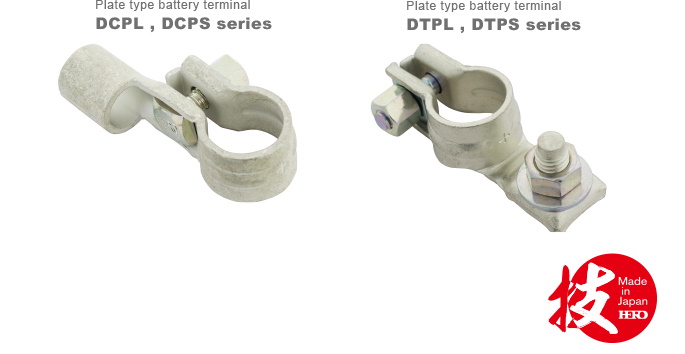

We adopted the material of terminal "Oxygen-free copper" which contents pure copper and its secular change of material is low level, and its conductivity exceeds the IACS level.

What is Oxygen-Free Copper?

| Material | Component | Feature | Examples of material use |

|---|---|---|---|

| Oxygen-Free Copper (JIS:C 1020) | Copper content rate: 99.96% or more | High-purity copper having properties of excellent conductivity, in which impurities contained are reduced to the minimum. It is often used as a material for electronic components, which has excellent malleability, fatigue resistance, corrosion resistance, and weather resistance. | Parts used for wiring circuit connection of generators, switchboards, audio equipment, etc. |

*Malleability: The property of material to evenly stretch and extend without being destroyed, even when it is pressed and stretched beyond its elastic limit.

Reference: Comparison list of conductivities of various materials

| Compared materials | Oxygen-Free Copper * Materials used by products | Brass | Zinc alloy diecasting | Lead |

|---|---|---|---|---|

| Material conductivity (IACS) | 101% | 28% | 26% | 9% |

*1. Material conductivity refers to the internationally adopted standard annealed mild copper as a standard of electric resistance, which is specified as 100%IACS conductivity.

*2. Above values are just general reference values (standards), not absolute values (guaranteed values)

Reference: Plating treatments used on automotive repair battery terminals

| Type of plating | Plating compatibility in automobile parts | Features | Example of products compatible |

|---|---|---|---|

| Tin-plating | Japan Industrial Standards(JIS) Automobile parts - General rules of electroplating | Plating applied mainly for corrosion and rust protection purposes |

|

| Copper plating |

| ||

| Brass plating | - | Plating applied mainly for decorative purposes |

|

Usage environment grades specified in Automobile parts-General rules of electroplating

| JIS grade | Usage environment |

|---|---|

| Grade 4 | Outside of the vehicle exposed to harsh environments |

| Grade 3 | Outside of the vehicle in ordinary environments |

| Grade 2 | Inside of the vehicle exposed to harsh environments |

| Grade 1 | Inside of the vehicle in ordinary environments |

Usage environments of plated products are classified into the above listed four grades

Usage environment JIS grade for each plating type specified in Automobile parts-General rules of electroplating

| Type of plating | JIS grade |

|---|---|

| Tin-plating | Grade 4 |

| Copper plating | - |

*1:No description on usage environment grade for copper plating under Automobile parts - General rules of electroplating

`2:Brass plating is omitted due to no stipulation under Automobile parts - General rules of electroplating

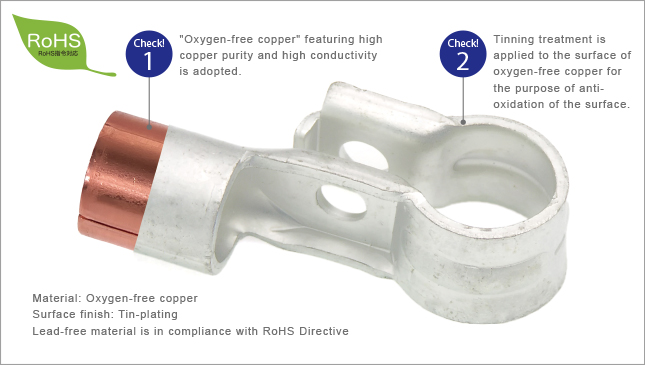

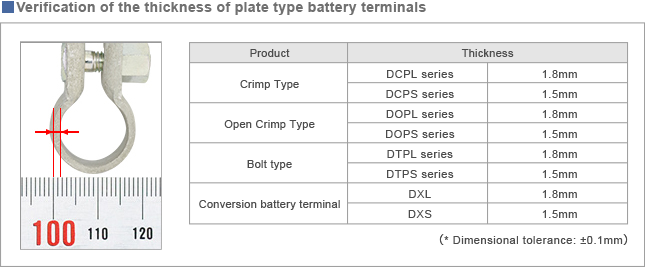

Remarkable point 3

To fulfill the battery' s function under the harsh environment in the engine room, we investigated 'the increment of the thickness' and 'slitless structure' of the battery terminals.

| Development concept | Reason and background |

|---|---|

| Thickness of terminal |

*Synergistic effect of Oxygen free copper |

| Slitless structure |

|

Reference: Verification of practical use examples of battery terminals with slits

The cracked battery terminal can causes 'contact

failure' and 'Voltage reduction' and fall into the

troubles of the vehicles.

Remarkable point 4

Our Plate-type battery terminals do not contents any hazardous chemical substances like lead, mercury, cadmium and based on the RoHS directive. We are manufacturing the ecological products to answer the needs of the age and supporting the environmental preservation.

One point advice in the case of using battery terminal

We recommend 'crimping' when you connect the battery terminal to electric wire, which is fully relied by the mechanics.

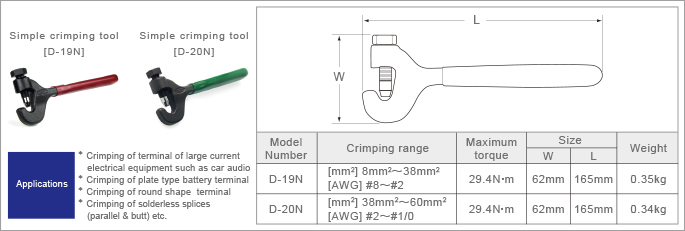

Our original crimping tools as 'D-19N & D-20N' enable to do the relief and secure crimping operation and its minimal tensile strength of the crimping point exceeds the JASO standard.

Verification of ross-sectional shape of crimping

D-19N and D-20N exceed the JASO standard of minimal tensile strength

Plate type battery terminal

Electrical wire

Fully exhibit its intrinsic storage battery performance by installing (crimping) battery terminals and electric wires more safely and more securely.

Engine vibration and traveling vibration of automobiles have an effect on the connection between "battery terminals" and "electric wires", causing voltage reduction and contact failure due to loosened connection. It also may cause death of battery or malfunction of electronics, so it is important to perfectly connect (crimp) battery terminals with electric wires.

JASO tandards: Industrial standards established by a public interest incorporated association called "the Society of Automotive Engineers of Japan (JSAE)"

Specifications

| Product | Type | Model Number | Standard specification | ||||

|---|---|---|---|---|---|---|---|

| Pole size | application | Pole | Materials | Surface finish | |||

|

Crimp Type | DCPL60-1 | Large pole | Internal diameter of crimping part φ12.5 Wire range 60.00mm2 | + | Oxygen-free copper | Tin-plating |

| DCPL60-2 | - | ||||||

| DCPL38-1 | Internal diameter of crimping part φ9.4 Wire range 38.00mm2 | - | |||||

| DCPL38-2 | - | ||||||

| DCPS22-1 | Small pole | Internal diameter of crimping part φ7.7 Wire range 22.00mm2 | + | ||||

| DCPS22-2 | - | ||||||

|

Bolt type | DTPL-1S | Large pole | Bolt type M8 | + | ||

| DTPL-2S | - | ||||||

| DTPS-1S | Small pole | - | |||||

| DTPS-2S | - | ||||||

|

Conversion battery terminal | DXL SET DXL PEAR SET |

In case of the existing battery terminal of vehicle is "small pole" and thenew replacement battery is "large pole" (high electric capacitance type) | + - |

Main Body Material: Oxygen-free copper Sleeve Body Material: Brass |

Main Body Surface finish: Tinning treatment Sleeve Body Surface finish: Non processed |

|

|

DXS SET DXS PEAR SET |

In case of the existing battery terminal of vehicle is "large pole" and the new replacement battery is "small pole" (high electric capacitance type) | + - |

||||